When Double Glazing “Melts” from the Inside: A Hidden Failure Risk

Double glazing units form a durable maintenance-free solution which delivers superior thermal performance together with soundproofing and humidity management.

Even the top-tier insulated glass units (IGUs) experience internal sealant failure which causes dark sealant migration into the unit’s interior.

The article investigates the factors behind this occurrence while analysing its consequences and testing procedures before describing how vacuum insulated glazing technology prevents this specific problem.

What Do We Mean by “Melting” Inside Double Glazing?

The inside section of double glazing undergoes a melting transformation because the edge-seal materials which include black primary seal at the spacer bar perimeter experience softening and migration and creep processes.

The materials will shift within the glass pane spacing when heat causes their deformation which leads to black stains and web-like patterns in the glass chamber.

The sealing system failure allows both gas to escape and moisture to enter which creates a condition that exceeds regular condensation and dirt build up.

Anatomy of an IGU: Seals, Spacers, and the Vulnerable Edge Zone

Understanding this problem starts with learning about the basic functionality of standard double glazing units.

- The spacer bar runs along the edges of two glass panes to maintain their separation distance.

- The space between the panes is commonly filled using air or argon gas as insulating material.

- The two-stage sealed system includes:

- Primary seal (often hot melt butyl or polyisobutylene “PIB”) which creates the initial gas and moisture barrier

- Secondary (outer) seal made of polysulphide, polyurethane, silicone or structural sealants which provides unit integrity through its mechanical function

The unit’s edge zone represents the most thermally stressed part of the system.

The combination of aluminium or warm-edge spacer allows heat transfer while sunlight exposure can produce high local temperatures which affect the glass edge regions in south and west facing windows.

The primary seal will start migrating when the secondary seal shows signs of weakness and improper curing and when it develops cracks and brittleness during the ageing process.

Why Does the Black Sealant Soften or Migrate?

The following factors stand as primary causes of this problematic condition:

1. Sealant Formulation that Fails to Meet Adequate Standards

Manufacturers produce some sealants using reduced grade hot melt or butyl which have softening points lower than 60 degrees Celsius.

Dark frames combined with reflective environments during intense sun exposure create local temperatures that surpass the sealant’s softening point. The sealant transforms into a semi-liquid form that gradually shifts inside the glass panel area.

2. Problems with Secondary Seal Quality or Failure of Bonding

The secondary seal needs to perform two functions which are to provide mechanical support and to stop the primary seal from moving.

The primary seal will start moving when the secondary seal does not properly cure and when it develops brittleness through the years.

3. Exposure to Time, UV (ultraviolet) Light and Cycling Temperature Changes

Seal materials break down because of UV light exposure and temperature changes as well as moisture penetration and plasticizer depletion.

Thermal exposure to the seal can cause it to become soft or sticky which results in reduced motion resistance when heated.

4. Concentrated Solar Heating / Reflective Surfaces

Direct sunlight along with low-e coatings and reflective surfaces on windows will add heat to the area. The heat from direct sunlight on the window surfaces of windows can reach high temperatures which cause butyl or bitumen-based seals to soften.

5. Manufacturing / Quality Control Defects

Companies that apply insufficient sealant or form defective bonds during the manufacturing process create weak spots which allow thermal stress to cause leaks in the resulting products.

How to Recognize the Problem

If your double glazing develops signs of internal “melting” you should look out for these symptoms:

- The presence of black marks or stains inside the glazing gap specifically near the spacer bar

- Watch for thin strings of material that extend from the spacer towards the inside of the unit

- The seal becomes loose, or the edges turn soft and sticky because of external contact

- Condensation inside the glass pane with rainbow patterns signals that the seal has failed and gas has leaked out.

- Look for unusual visual effects or shadowy spots near the edges of the glass.

Photography of the sealed unit interior through strong backlighting makes it easy to detect moving material between the glass panels.

Once the seal begins to fail the unit stops functioning correctly because argon gas starts to escape and moisture begins to enter. The unit’s insulating performance will degrade rapidly.

Consequences of Sealant Failure

- The insulating gas escapes while moisture enters the space between the panes which leads to reduced thermal performance.

- The space between the panes becomes foggy because moisture enters the cavity.

- A unit that fails can hardly be resealed reliably from the outside.

- The problem requires complete IGU replacement because seal repairs do not work in most cases.

- The warranty becomes invalidated when there is a failure in the seal.

When a manufacturer or installer encounters these issues they face significant liability because these problems reflect their quality control processes and material specifications and product durability over time.

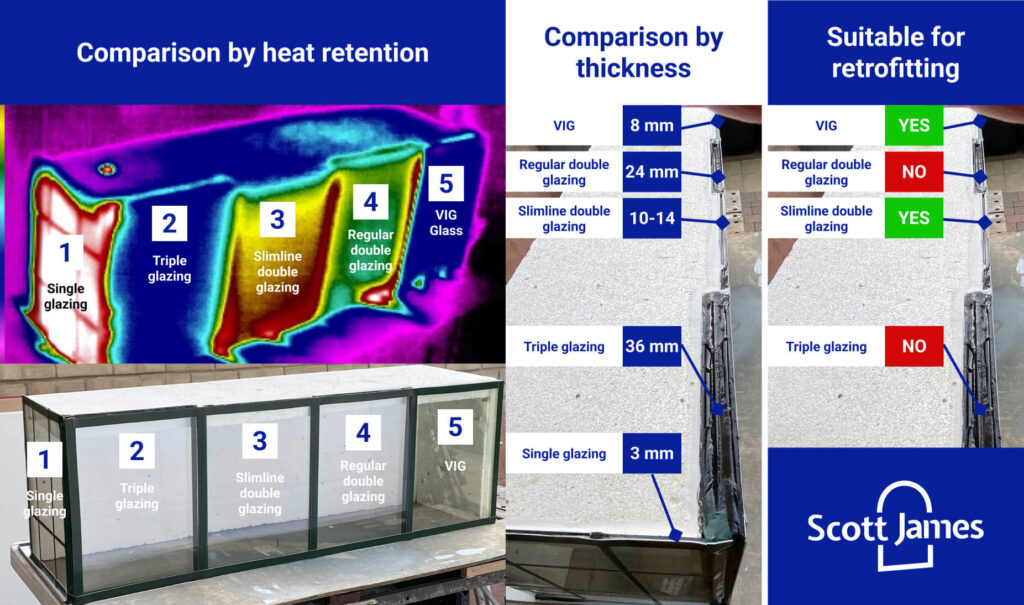

Why VIG (Vacuum Insulating Glass) Avoids This Problem

The technology of Vacuum Insulating Glass (VIG) functions without requiring enclosed gas spaces.

The technology relies on the following components:

- The vacuum between two glass panes is maintained by tiny micro-spacers (often microscopic pillars)

- The vacuum system eliminates the possibility of heat transfer through both conduction and convection in the space.

- The elimination of gas maintenance requirements together with edge seal containment needs allows standard failure modes affecting traditional IGUs to vanish.

The VIG technology offers the following benefits:

- The absence of butyl or hot melt edge seal age prevents migration or “melting” problems from developing.

- Seal degradation over time does not occur due to the absence of sealants.

- Stable long-term thermal performance — since there’s no gas to leak out

A comparison between traditional faulty IGUs with sealant migration and VIG panels demonstrates that complete failure mode prevention exists in Vacuum Insulating Glass technology.

Key Takeaways for Window Buyers & Owners

- If you see black smears inside your glazing, take action immediately.

- Dual-seal IGUs require primary PIB and hot melt along with robust secondary structural seal.

- Make sure to get temperature specifications for edge seals before ordering replacements and select units with sealants that remain stable above 90 degrees Celsius.

- The orientation and frame colour inspection should focus on dark frames and sun-exposed façades because they intensify thermal stress.

- Investing in VIG technology provides a sealant creep-proof solution which eliminates the risk of gas loss.

Final Thoughts

The black sealant contained within double-glazed units experiences melting which occurs as a hidden failure risk that generates serious problems. The edge-seal system displays signs of failure because insulating gas will escape and moisture will start to enter the system.

Under extreme heat and ageing conditions conventional IGUs with butyl or hot melt sealants will fail when materials and manufacturing quality do not meet standards.

A Vacuum Insulating Glass unit does not need sealed gas spaces to function.

The system operates without butyl seals or secondary structural seals, and it maintains stable performance throughout its operational life.

Scott James Windows needs to teach their customers about conventional sealed unit risks and how modern VIG technology provides superior benefits.

Using precise specifications combined with direct communication helps you decrease failure rates and protect warranties while delivering durable glazing solutions that perform for extended periods.

Read more articles

Safety glass regulations, UK

Safety glass regulations, UK

Victorian windows

Victorian windows

What is FENSA, and how does it affect you?

What is FENSA, and how does it affect you?