Sash windows are a fairly complex design with many different parts contributing to their effective functioning. Emerging towards the end of the 1600s and seeing a boom in their use through the Georgian period, some parts and design interpretations have changed over the subsequent 300+ years of use.

However, many fundamental elements remain the same, some of which will be explored below.

This really is a testament to the incredible and enduring design of the sash window which combines elegant looks with utility.

Key sash window anatomy word overview

Sash window parts diagram:

Architrave– a moulded perimeter trim covering the frame and the wall. Becoming increasingly ornate into the Victorian era. We usually replace the whole architrave section when we repair sash windows.

Bottom sash– bottom window which general slides up to be fixed in situ on a level with the top sash while the window is in the open position.

Catch- Sash window catches and fasteners come in a lot of different varieties and serve to provide a lock point between the two windows fixing them in a closed position. One of the most enduring designs is the fitch fastener.

Frame– traditionally a wood construction that holds the glass in place. Made up of horizontal rails and vertical stiles with older sashes (i.e. Georgian) also featuring numerous glazing bars between the smaller glass panes.

Glazing– the glass held between the timber frame. Changing in format greatly over historical periods consisting initially of multiple small glass panes separated and held by wooden glazing bars developing into units with often just 1 pane per sash.

Windowhead drip– fixed horizontally to the top of the window casing directing rain away from the window.

Sash window horn– timber protrusions from the upper sash meeting rail, often ornate in design. They were added to strengthen the joints on the timber window frame as it had to bear an increasingly heavyweight with the advent of larger panes of glass through the Victorian period.

Jamb– sitting inside the framing of the window and acting as structural support to the sash. When running vertically they are known as side jambs and horizontally as head jambs.

Meeting rails- the horizontal meeting rail between the lower and upper sash.

Pulley– the mechanism through which the sash cord is fed helping the sashes to open and close smoothly.

Putty– used to weather-proof and seal gap between the glazing and sash window frame.

Sash bars– the wooden runs separating and providing support to individual panes of glazing within the window unit (providing the sashes are made up of more than 1 pane per unit). Window styles usually are different by the number and formation of glazing bars.

Sash stiles– the wood running vertically up either side of the sash window.

Sash weights– provides the effective counterbalance so windows can remain in the fixed open position (i.e. self-supporting) without the risk of unwanted closure.

Sash window trim- the stationary decorative pieces of trim surrounding the sash window frame not involved in the window’s operation.

Staff bead- the trim which keeps the sash in place in the sash box, traditionally made from wood.

Stone window sill- the horizontal stone structure at the bottom of the window frame, provides support and acts to shed rainwater.

Top sash– generally the fixed window of the pair.

Wooden window sill- has the same function as the stone sill except in timber.

Window board/nosing- also known as the sill and running horizontally across the base of the sash window.

Key sash window parts in more detail

Sash cord:

Moving through the pulleys, this is the rope (counterbalanced by sash weights) that pulls the box sash windows up and down. Often bought waxed which acts as a mild lubricant when passing through the pulley system.

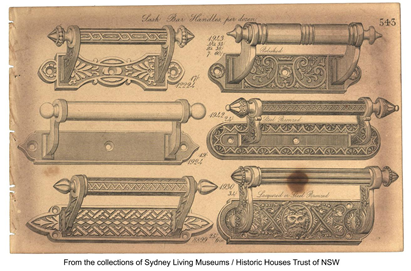

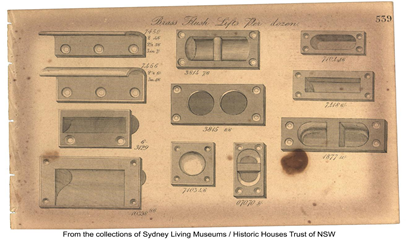

Sash lifts:

The mechanism attached to the bottom sash through which the window is lifted, most commonly including handles and the simpler recess format.

With styles changing to suit the trend of the period, the Victorian and Edwardian era specifically saw a particularly ornate phase of sash lifts and handles some of which are pictured below

More ornate sash lifts above with simpler recess style lifts pictured below

Sash fasteners and catches:

The mechanism which fixes the sash windows in a closed position. Some of the key designs were:

-Quadrant fastener: a plate with a lever attached to the top sash which, when moved through 90 degrees, locks into a receiving mechanism on the lower sash

-Claw fastener: many similarities to the quadrant fastener except that the hook body is fixed to the bottom sash and the keep plate to the top

-Fitch fastener: this design was very popular through the 1800s and remains in heavy use to this day. Again, the body is fixed to the lower sash with the fixture rotating into a clasp catch on the top sash

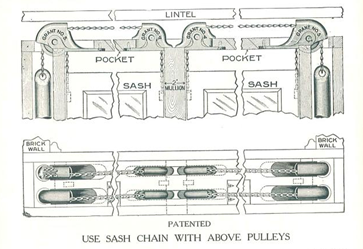

Pulley:

The mechanism through which the sash rope/chain is fed as the window is open and closed. A reliable pulley system is a key to the proper functioning of the window. Into the 20th century with the replacement of sash cords with chains, the accompanying pulley system also had to adjust to becoming more durable and operational with metal.

Early 20th century example of a newly patented US metal sash pulley system

Materials used during sash window repair & maintenance

Timber sash windows have often been in place on properties for decades or centuries. Naturally with the passing of this time, and exposure to the elements, degradation of the window unit occurs.

Therefore intermittent maintenance, and sometimes more major repair work, is needed to keep the window functional and weatherproof.

Putty:

The material used to fill and weatherproof the gap between panes of glazing on sash windows and the timber frame. Similar to what we might recognise as a ‘filler’ type product but with specific durable and weather-proof properties that make it ideal for this purpose.

Wood filler:

A key resource is used to fill all surface and deeper holes on the wooden window unit. A long-lasting and durable product which, once painted over, blends in seamlessly to the window.

Sash window design change over time

Due to their longevity, with nearly 400 years of continuous use, some key changes have understandably taken place in sash window parts and designs over time. Some of the primary amongst these are changes in the quality of glass, leading to increased pane size over time, with resulting effects on frame design.

Through the early Georgian era of the sash, limitations in glass production meant panes were restricted in size giving rise to the characteristic window of this period with many small glass panes per sash separated by wooden glazing bars (commonly including 8 over 8 up to 16 over 16 sashes).

However, moving through into the Victorian period, and with increasing quality in glass production, sash windows were being produced with up to single sheets of glazing per sash changing the look of the window quite radically with the previously numerous glazing bars now gone. Another knock-on effect of this (as mentioned briefly earlier) was the need for increased use of sash horns, these gave extra strength to the timber frame which now had to hold in place larger and fewer panes of glass.

6 over 6 Georgian sashes with marginal glazing bars on display

1 over 1 Victorian sashes showcasing the developments in glassmaking technology

Read more articles

What is FENSA, and how does it affect you?

What is FENSA, and how does it affect you?

Permanent insulation for windows

Permanent insulation for windows

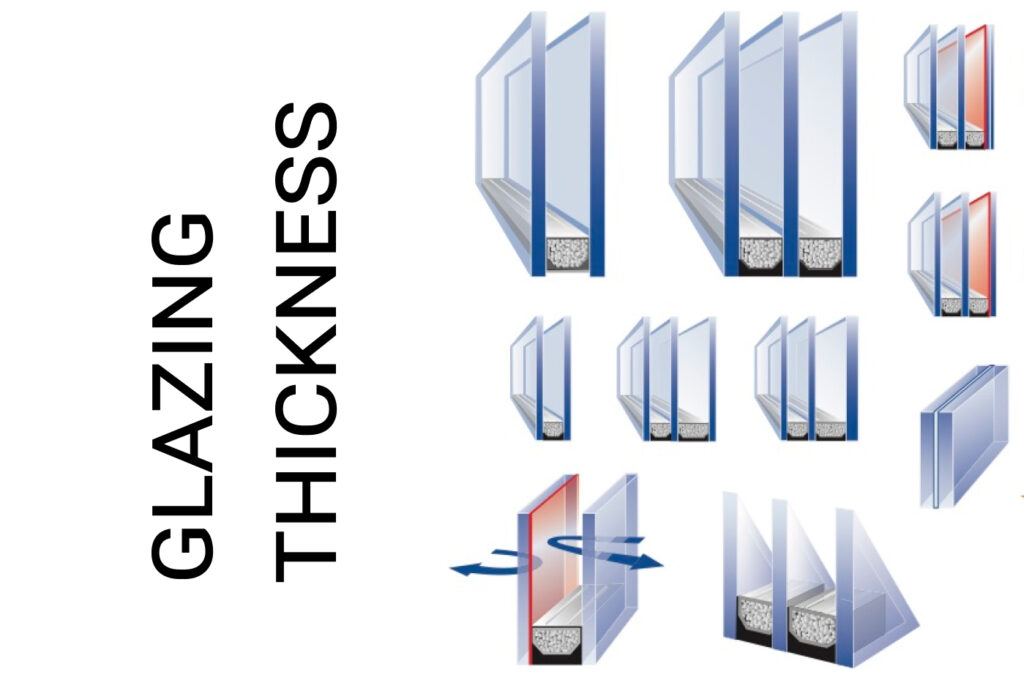

Double glazing thickness

Double glazing thickness